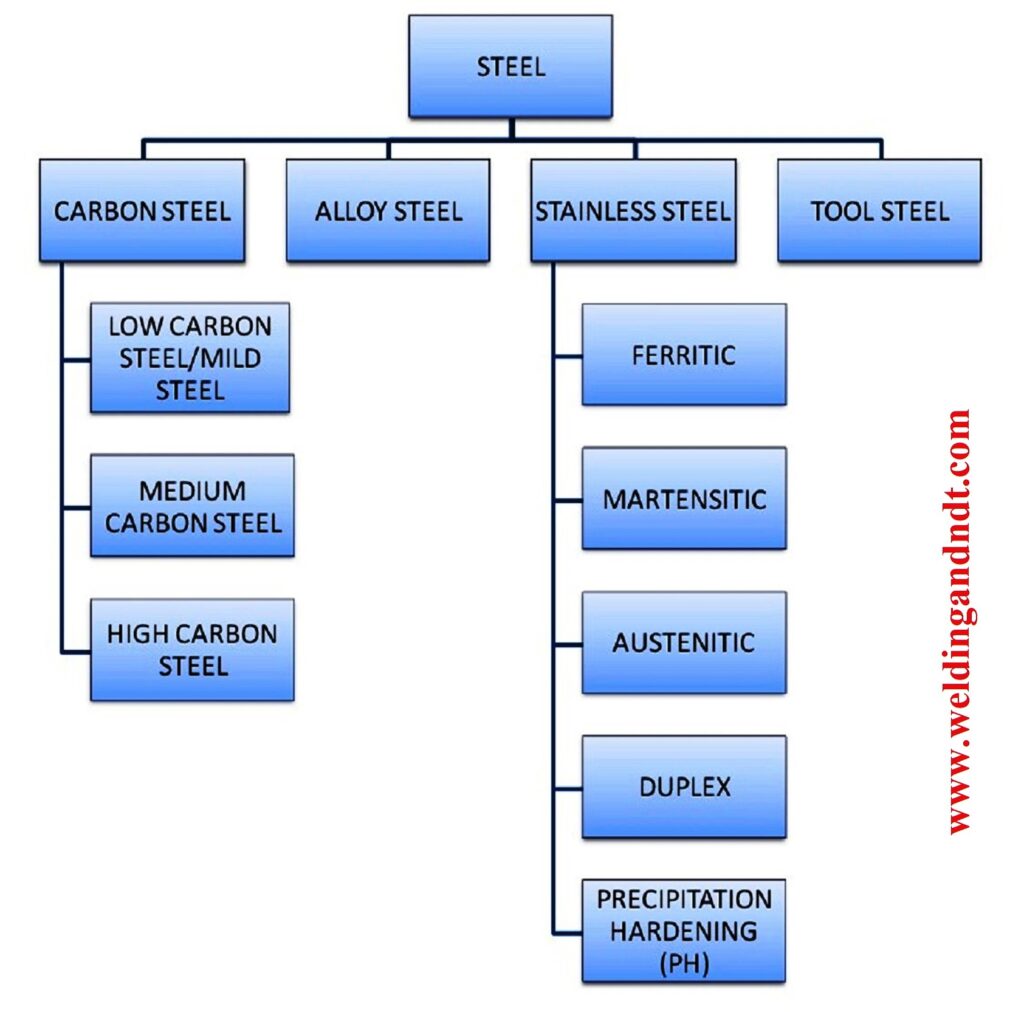

Steel is a versatile alloy primarily composed of iron and carbon, with various other elements added to achieve specific properties. Below are the main types and variations of steel:

- Carbon Steel

Low-Carbon Steel (Mild Steel): Contains up to 0.25% carbon. It’s ductile, malleable, and used in construction and automotive parts.

Medium-Carbon Steel: Contains 0.25–0.60% carbon. It offers a balance of strength and ductility and is used for gears and railway tracks.

High-Carbon Steel: Contains 0.60–1.5% carbon. It’s hard and brittle, often used for cutting tools and springs.

- Alloy Steel

Steel with elements like chromium, nickel, vanadium, molybdenum, or manganese to enhance specific properties.

Examples:

Chromium Steel: Improved wear and corrosion resistance.

Nickel Steel: Enhanced toughness and low-temperature performance.

- Stainless Steel

Contains at least 10.5% chromium, which provides corrosion resistance.

Types of Stainless Steel:

Austenitic: Non-magnetic, highly corrosion-resistant (e.g., 304 and 316 grades).

Ferritic: Magnetic and corrosion-resistant, but less ductile.

Martensitic: Magnetic, high strength, used in cutlery.

Duplex: A mix of austenitic and ferritic, offering strength and corrosion resistance.

Precipitation-Hardening: Excellent strength with moderate corrosion resistance.

- Tool Steel

High hardness and resistance to abrasion, used for tools, dies, and molds.

Common types:

High-Speed Steel (HSS): For cutting tools.

Water-Hardening (W-Grade): Affordable and used in low-heat applications.

Shock-Resistant Steel (S-Grade): Handles high-impact applications.

- Specialty Steels

Maraging Steel: Ultra-high strength and toughness, used in aerospace and tooling.

Weathering Steel (Corten Steel): Forms a protective rust layer, used in outdoor structures.

Electrical Steel: Used in transformers and motors for its magnetic properties.

- Galvanized Steel

Coated with zinc for rust resistance, commonly used in roofing and fencing.

- Spring Steel

High elasticity and fatigue resistance, used in springs and suspension systems.

Each variation is tailored for specific applications by adjusting the composition and processing methods.