Refractory materials are specialized industrial substances capable of withstanding extremely high temperatures, often exceeding 1,000°C (1,832°F). They are essential in various high-temperature industrial processes where durability, thermal stability, and resistance to chemical attack are required.

Characteristics of Refractory Materials:

- High Melting Point: Withstand temperatures without melting or softening.

- Thermal Stability: Maintain structural integrity under rapid temperature changes.

- Chemical Resistance: Resist corrosion from slag, gases, or molten materials.

- Mechanical Strength: Retain strength under high-stress conditions and thermal cycling.

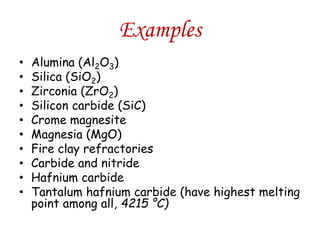

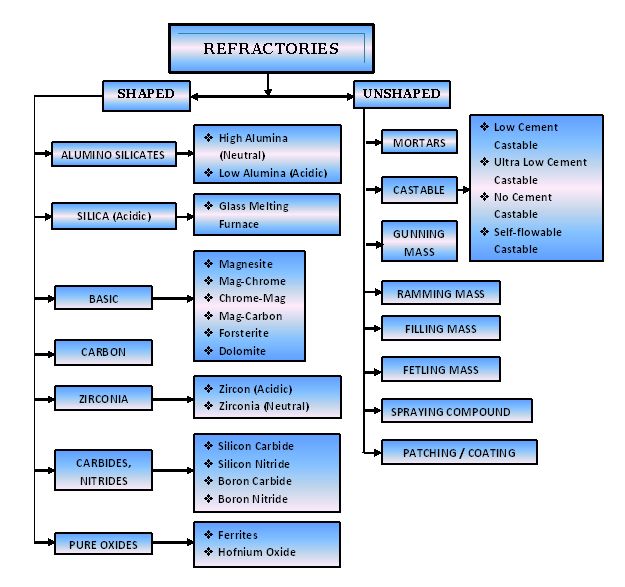

Types of Refractory Materials:

- Acidic Refractories: Made of silica or zirconia; used where acidic environments prevail.

Example: Silica bricks.

- Basic Refractories: Made of magnesia or dolomite; suited for basic environments.

Example: Magnesia bricks.

- Neutral Refractories: Compatible with both acidic and basic conditions.

Example: Alumina and chromite.

Applications:

Steel Industry: Linings for blast furnaces, converters, and ladles.

Cement Production: Kiln linings and coolers.

Glass Industry: Melting tanks and regenerators.

Petrochemical Industry: Catalytic cracking units.

Power Plants: Boilers and incinerators.

These materials are critical for energy efficiency and operational safety in high-temperature industrial applications.