Primary steelmaking is the process of converting raw materials, such as iron ore and coke, into steel. It involves two main principles: the removal of impurities and the adjustment of chemical composition to achieve desired properties. Here’s a breakdown of the principles involved:

- Oxidation of Impurities

The primary goal is to remove impurities such as carbon, silicon, sulfur, phosphorus, and manganese from the raw iron (usually pig iron or hot metal).

This is achieved by oxidation, where oxygen reacts with these impurities to form gaseous or slag by-products:

Carbon reacts with oxygen to form carbon monoxide (CO) or carbon dioxide (CO₂).

Silicon, manganese, phosphorus, and sulfur are oxidized and absorbed into the slag.

These reactions are exothermic, releasing heat that helps maintain the high temperatures required for the process.

- Decarburization

Carbon content is reduced to achieve the desired steel composition.

Oxygen is blown into the molten iron, reacting with carbon to form CO or CO₂ gases, which escape from the melt.

- Slag Formation

Slag, a by-product, is formed by adding fluxing agents such as limestone (CaCO₃) or dolomite.

It captures impurities (like sulfur and phosphorus) and prevents the reintroduction of unwanted elements into the steel.

Slag also acts as an insulator, maintaining the high temperature of the molten metal.

- Heat Balance

The process must maintain high temperatures (~1600°C) to keep the metal molten and allow efficient reactions.

Heat is generated through exothermic oxidation reactions and the combustion of coke.

- Chemical Composition Control

Alloying elements such as chromium, nickel, or vanadium can be added to achieve specific steel grades.

Oxygen flow and slag chemistry are carefully controlled to achieve precise chemical specifications.

Methods of Primary Steelmaking:

Basic Oxygen Furnace (BOF): Uses pure oxygen to refine pig iron and scrap steel into steel.

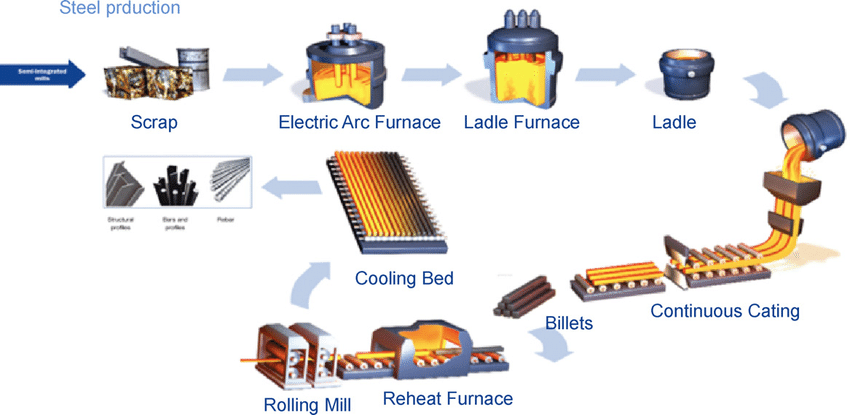

Electric Arc Furnace (EAF): Though more common in secondary steelmaking, EAFs can also process raw materials by melting scrap steel and iron.

By adhering to these principles, primary steelmaking ensures the production of high-quality steel suitable for various industrial applications.