A fancy steel chair is made through a series of steps involving design, material selection, cutting, shaping, and finishing. Here’s a general overview of the process:

- Design

Conceptualization: The chair’s design is created, often with CAD software, ensuring that it meets aesthetic and functional requirements.

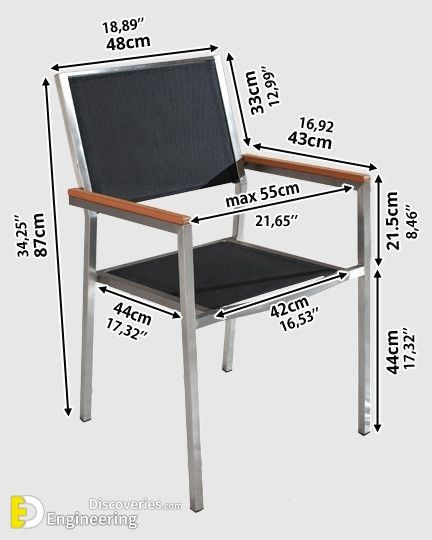

Measurements and Ergonomics: The dimensions are specified to ensure the chair is comfortable and stable.

- Material Selection

Steel Choice: Typically, stainless steel or mild steel is selected based on strength, durability, and whether a polished or brushed finish is desired.

- Cutting

Laser Cutting or Plasma Cutting: The steel sheets or bars are cut into the required pieces using laser or plasma cutting machines, ensuring precision in the design features.

Tubular Steel: For the frame or legs, steel tubes are often used, which are cut to size using tube-cutting equipment.

- Shaping and Forming

Bending: The cut steel pieces are shaped into curves or angles as per the design, using metal benders or hydraulic press brakes.

Welding: The shaped parts are welded together, creating the frame of the chair. Skilled welders ensure the joints are smooth and seamless.

- Surface Finishing

Grinding: The welds are ground down to ensure a smooth surface.

Polishing: Stainless steel may be polished to a mirror finish or brushed for a matte look. Mild steel may require powder coating or paint for rust protection.

Coating: If a specific color or texture is desired, the steel frame can be powder-coated or painted to give a durable, attractive finish.

- Assembly

Attachment of Additional Elements: If the chair has cushions, leather, or fabric components, these are fitted onto the frame. Armrests, backs, and other details are added.

Fastening: Screws or rivets might be used to attach different sections or decorative elements.

- Quality Check

The chair undergoes quality checks for structural integrity, finish quality, and overall design consistency.

- Final Touches

Inspection and Packaging: After the final inspection, the chair is cleaned, polished, and packaged for shipping.

Each chair may vary in complexity depending on the level of detail, material, and custom features involved.