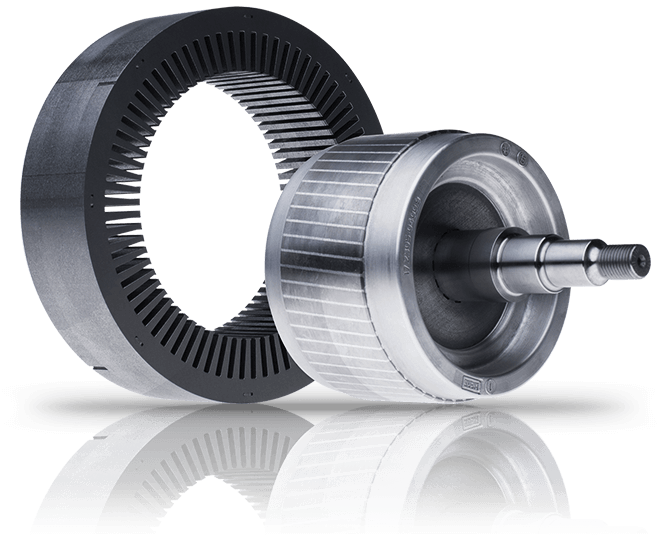

Electrical steels are specialized ferromagnetic materials primarily used in the cores of transformers, motors, and generators. Their primary purpose is to enhance the efficiency of electrical machines by reducing energy losses caused by hysteresis, eddy currents, and magnetic saturation.

Key Features of Electrical Steels:

- High Magnetic Permeability: Enables efficient magnetic flux conduction, minimizing core losses.

- Low Core Losses: Achieved by reducing hysteresis and eddy current losses.

- Controlled Alloying Elements: Silicon is a major alloying element, enhancing resistivity and reducing eddy current losses.

- Thin Lamination: The steel is often rolled into thin sheets and laminated to further reduce eddy currents.

Types of Electrical Steels:

- Grain-Oriented Electrical Steel (GOES):

The grains are aligned to optimize magnetic properties in a specific direction.

Used in transformers and some specialized applications.

Features high permeability in the rolling direction and low core loss.

- Non-Grain-Oriented Electrical Steel (NGOES):

Grains are randomly oriented, offering uniform magnetic properties in all directions.

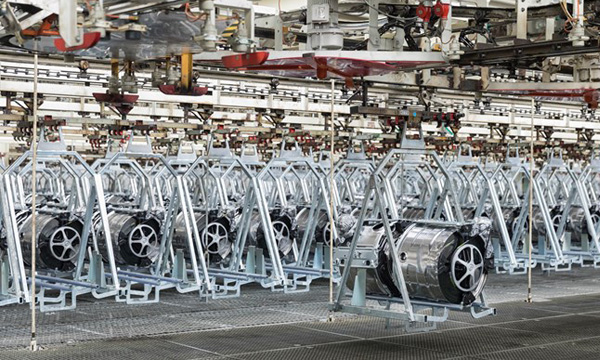

Typically used in rotating machines such as motors and generators.

Manufacturing Processes:

- Cold Rolling: Produces thin sheets and improves the steel’s grain structure.

- Annealing: Refines the grain structure, enhancing magnetic properties.

- Coating: Applies an insulating layer to prevent eddy currents between laminations.

Applications:

Transformers: Use GOES for efficient magnetic flux conduction.

Electric Motors: Use NGOES for uniform magnetic performance.

Generators: Use NGOES for reducing losses at high rotational speeds.

Future Trends:

With the rise of renewable energy and electric vehicles, demand for advanced electrical steels with even lower losses and higher efficiency is increasing. Innovations include:

High-silicon steels for higher resistivity.

Nano-crystalline materials for ultra-low core losses.