The Evolution of Steel: From Ancient Times to Modern Applications

Steel, an alloy of iron and carbon, has played a transformative role in human history, shaping civilizations and modern industries. Its development over millennia reflects the progress of science, technology, and human ingenuity. Here’s an overview of the evolution of steel:

Ancient Beginnings: Early Metallurgy

Iron Age (~1200 BCE):

The transition from the Bronze Age to the Iron Age marked the beginning of widespread iron usage. Early blacksmiths discovered that heating and hammering wrought iron increased its strength. This was the precursor to steelmaking, as small amounts of carbon were unintentionally introduced during forging.

Wootz Steel (300 BCE – 600 CE):

In ancient India, artisans mastered the production of wootz steel, known for its high carbon content and remarkable strength. This steel became famous for its use in Damascus swords, prized for their resilience and sharpness.

Medieval Innovations

Pattern-Welded Steel (500 – 1500 CE):

During the medieval period in Europe, blacksmiths created “pattern-welded” steel by forging together layers of iron and steel. The resulting material was both durable and flexible, ideal for weapons like swords and axes.

Blast Furnaces (14th Century):

The development of blast furnaces in China and later in Europe allowed for the mass production of pig iron, a crucial step toward modern steelmaking.

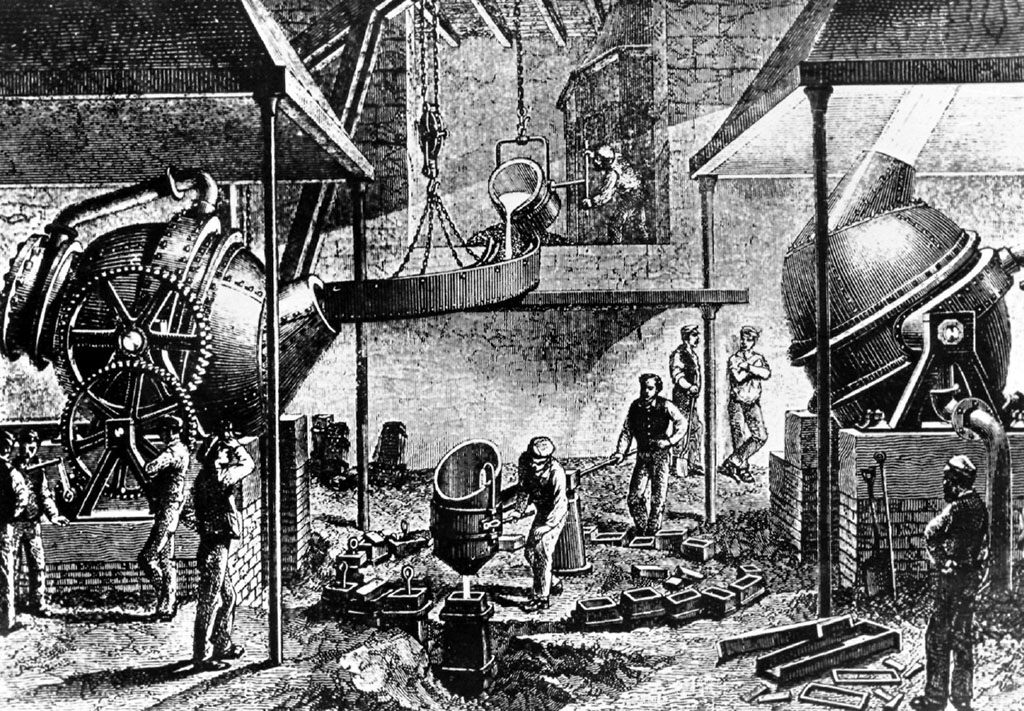

Industrial Revolution: The Birth of Modern Steel

Bessemer Process (1856):

Henry Bessemer revolutionized steel production by inventing a method to remove impurities from pig iron using blasts of air. This process dramatically reduced costs and increased production, making steel accessible for railroads, bridges, and buildings.

Open-Hearth Furnace (1860s):

The open-hearth furnace improved steel quality by allowing better control of carbon content and impurities. It became the dominant steelmaking method by the late 19th century.

Alloyed Steels (Late 19th Century):

Advances in chemistry led to the development of alloyed steels, such as stainless steel, which resist corrosion, and tool steels, which are exceptionally hard and durable.

20th Century: Steel in the Modern Age

Electric Arc Furnace (EAF, 20th Century):

The EAF allowed for the recycling of scrap steel and the production of high-quality alloys, contributing to more sustainable practices in the steel industry.

World Wars:

Steel production soared during the World Wars, driven by the demand for weapons, vehicles, and infrastructure. Innovations in steel alloys supported the development of tanks, ships, and aircraft.

Automotive and Aerospace Industries:

The mid-20th century saw steel’s widespread use in automobiles, skyscrapers, and aerospace applications. High-strength, low-alloy steels became essential for lighter, stronger materials.

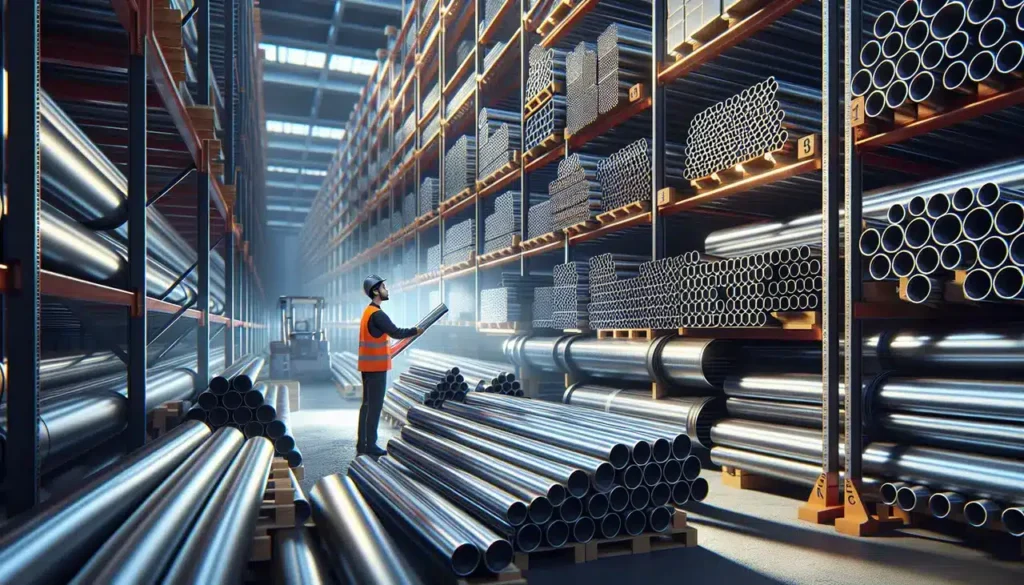

21st Century: Advanced Applications and Sustainability

High-Strength Steels:

Modern steel alloys are engineered for extreme strength and low weight, critical for industries such as automotive manufacturing and construction.

Nanotechnology:

Advances in nanotechnology enable the production of ultra-strong steels with tailored properties for specific applications, from medical devices to space exploration.

Green Steel Initiatives:

Environmental concerns have spurred efforts to reduce the carbon footprint of steel production. Technologies like hydrogen-based reduction and carbon capture aim to make steelmaking more sustainable.

Conclusion

From the forging fires of ancient blacksmiths to the high-tech laboratories of today, steel has continuously evolved, shaping and being shaped by human innovation. Its versatility and strength ensure it remains indispensable in industries ranging from construction and transportation to medicine and energy, embodying the resilience and adaptability of human progress.