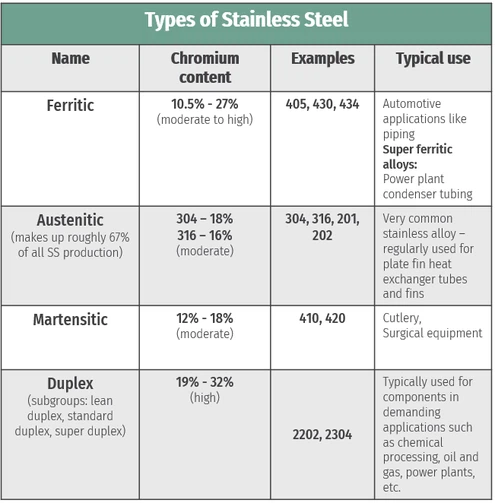

Stainless steel is a highly versatile material, and its properties can vary significantly depending on its composition and treatment. Here are the main variations of stainless steel, categorized by their metallurgical structure:

- Austenitic Stainless Steel

Characteristics:

High corrosion resistance.

Excellent formability and weldability.

Non-magnetic in annealed condition (can become slightly magnetic when worked).

High-temperature and low-temperature performance.

Common Grades:

304: General-purpose stainless steel; good corrosion resistance.

316: Improved corrosion resistance (contains molybdenum, ideal for marine and chemical applications).

310: High-temperature resistance.

- Ferritic Stainless Steel

Characteristics:

Moderate corrosion resistance.

Magnetic.

High resistance to stress corrosion cracking.

Good ductility, but not as strong as austenitic types.

Common Grades:

430: Decorative applications; good resistance to oxidation and corrosion.

409: Used in automotive exhaust systems (resists oxidation).

- Martensitic Stainless Steel

Characteristics:

High strength and hardness.

Magnetic.

Lower corrosion resistance compared to austenitic and ferritic types.

Can be heat-treated for enhanced strength.

Common Grades:

410: General-purpose, with moderate corrosion resistance.

420: Often used in cutlery due to its sharp edge retention.

440C: High hardness and corrosion resistance (ideal for tools).

- Duplex Stainless Steel

Characteristics:

Mixture of austenitic and ferritic structures (about 50/50).

Higher strength than either austenitic or ferritic stainless steels.

Excellent resistance to stress corrosion cracking.

Common Grades:

2205: High strength and corrosion resistance.

2507: Super duplex, designed for harsh environments.

- Precipitation-Hardening Stainless Steel

Characteristics:

Extremely high strength.

Can be heat-treated to improve mechanical properties.

Good corrosion resistance.

Common Grades:

17-4 PH: High strength and moderate corrosion resistance.

15-5 PH: Improved toughness over 17-4 PH.

- High-Temperature Stainless Steel

Characteristics:

Designed for use at high temperatures.

Retains mechanical properties under thermal stress.

Common Grades:

330: Resistant to carburization and thermal cycling.

253 MA: High creep strength and oxidation resistance.

Each variation has specific applications, from kitchenware and construction to aerospace and chemical processing. The choice depends on the balance between strength, corrosion resistance, and other performance requirements.