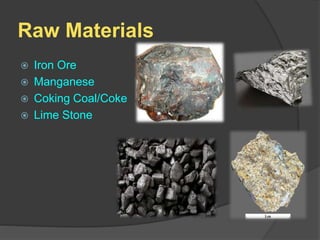

The raw materials used in steel production typically include:

- Iron Ore

The primary source of iron for steel production.

Commonly includes hematite (Fe₂O₃) and magnetite (Fe₃O₄).

- Coal/Coke

Coal is converted into coke, a purified form of carbon, which acts as both a fuel and a reducing agent in the blast furnace.

- Limestone

Used as a flux to remove impurities (like silica and phosphorus) from the iron ore during the smelting process.

Combines with impurities to form slag.

- Scrap Steel (Recycled Material)

Often used in Electric Arc Furnaces (EAF) to produce steel.

Reduces the reliance on raw iron ore and minimizes environmental impact.

- Other Additives

Manganese: Improves strength, toughness, and wear resistance.

Chromium: Adds corrosion resistance and hardness (used in stainless steel).

Nickel: Enhances corrosion resistance and toughness.

Silicon: Used as a deoxidizer.

Vanadium, Molybdenum, and Tungsten: Provide strength and wear resistance in specialized steel alloys.

These materials are processed in blast furnaces or electric arc furnaces, followed by refining to achieve the desired steel properties.