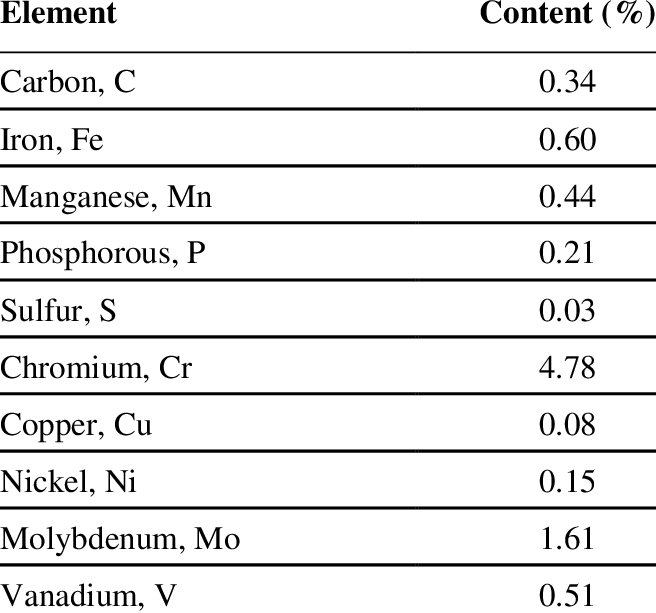

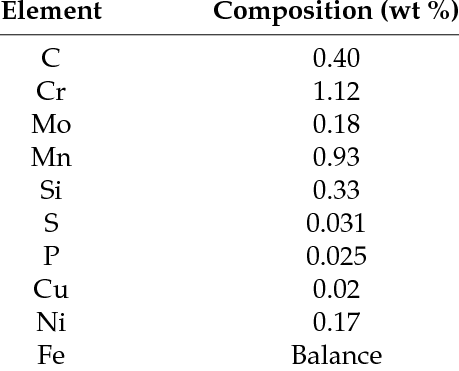

Steel is an alloy primarily made of iron (Fe) and carbon (C), with varying amounts of other elements depending on the specific type of steel and its intended application. The typical composition includes:

- Iron (Fe)

Forms the base material, making up the majority of the alloy (typically 98-99% in carbon steels).

- Carbon (C)

The primary alloying element in steel, typically ranging from 0.02% to 2.14% by weight.

Impacts hardness, strength, and ductility:

Low carbon steel: 0.02-0.25%

Medium carbon steel: 0.25-0.60%

High carbon steel: 0.60-1.00%

Ultra-high carbon steel: 1.00-2.14%

- Alloying Elements (varies by type of steel):

Manganese (Mn): Improves hardness, strength, and wear resistance. Typically 0.3–2.0%.

Chromium (Cr): Enhances corrosion resistance and hardness. Found in stainless steels (12% or more).

Nickel (Ni): Improves toughness and corrosion resistance. Found in stainless and alloy steels.

Molybdenum (Mo): Increases strength, toughness, and heat resistance.

Silicon (Si): Improves strength and deoxidizes the steel during production.

Vanadium (V): Enhances hardness, wear resistance, and strength.

Tungsten (W): Increases hardness and heat resistance.

Cobalt (Co): Used for high-speed steel; improves heat resistance.

Copper (Cu): Improves corrosion resistance.

- Impurities (undesirable, controlled during manufacturing):

Sulfur (S): Can make steel brittle but is sometimes added in controlled amounts for machinability.

Phosphorus (P): Increases strength but reduces ductility and toughness.

The specific composition of steel determines its properties and applications, ranging from construction and automotive uses to high-performance tools and medical devices.