Steel is classified based on its chemical composition, properties, and applications. Here are the main types of steel:

- Carbon Steel

Low Carbon Steel (Mild Steel): Contains 0.05%–0.25% carbon; used in construction, pipelines, and automotive parts.

Medium Carbon Steel: Contains 0.25%–0.60% carbon; used in gears, railway tracks, and structural steel.

High Carbon Steel: Contains 0.60%–1.5% carbon; used in cutting tools, springs, and high-strength wires.

- Alloy Steel

Contains elements like chromium, nickel, manganese, molybdenum, or vanadium to improve strength, corrosion resistance, or toughness.

Examples:

Chromium Steel: Resistant to wear and corrosion.

Nickel Steel: High strength and toughness.

Manganese Steel: High impact strength.

- Stainless Steel

Contains at least 10.5% chromium, offering excellent corrosion resistance.

Subtypes:

Austenitic Stainless Steel: Non-magnetic; used in kitchenware and chemical plants.

Ferritic Stainless Steel: Magnetic; used in automotive parts and industrial equipment.

Martensitic Stainless Steel: Hard and strong; used in knives and surgical instruments.

- Tool Steel

High hardness, resistance to wear, and heat resistance; contains tungsten, molybdenum, or cobalt.

Used in cutting, molding, and shaping tools.

- Structural Steel

Designed for use in construction; high tensile strength and flexibility.

Includes shapes like I-beams, channels, and angles.

- Special Steels

Maraging Steel: Ultra-high strength with good toughness; used in aerospace and tooling.

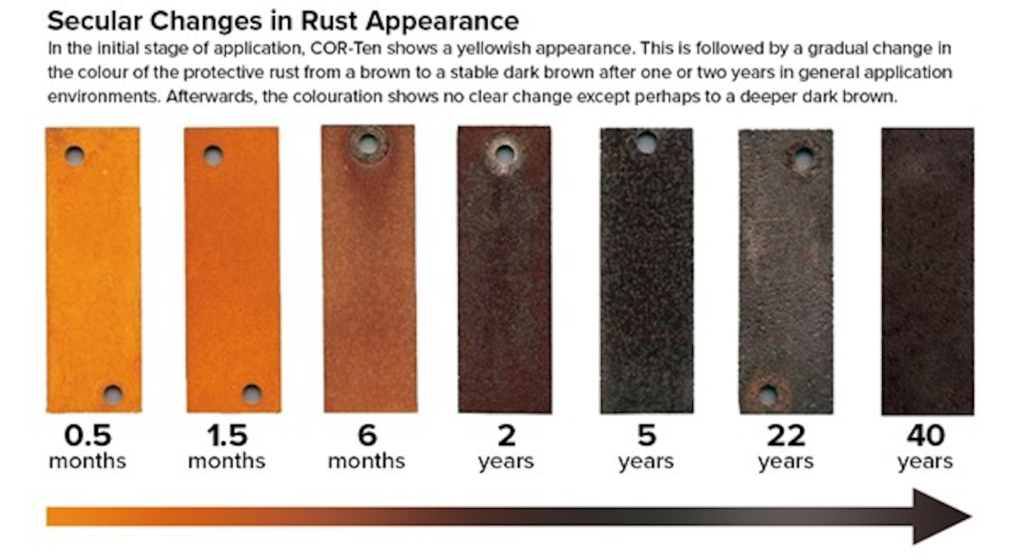

Weathering Steel (Corten Steel): Forms a protective rust layer; used in outdoor structures.

Electrical Steel: High magnetic permeability; used in transformers and motors.

Each type is tailored for specific applications based on its mechanical properties and composition.